How to solve the failure of stacker

In a professional point of view, if the malfunction of the stacker requires rapid troubleshooting and to recover its good performance, do not run on defective equipment, it would only increase the equipment damage, from the point of view of processing, there are two major types, one is users rely on their own troubleshooting, buy equipment, users must organize to investigate equipment, professional and technical personnel, then, if the device fails to do?

In a professional point of view, if the malfunction of the stacker requires rapid troubleshooting and to recover its good performance, do not run on defective equipment, it would only increase the equipment damage, from the point of view of processing, there are two major types, one is users rely on their own troubleshooting, buy equipment, users must organize to investigate equipment, professional and technical personnel, then, if the device fails to do?

Usually, the common faults can be solved in a timely manner, the difficulty is not high, the other method is to coordinate manufacturer to solve fault, fault for some difficulties, the user must contact manufacturer, let manufacturers to provide technical guidance and, when necessary, invite technicians to the door, it is concerned, many custom manufacturer stacker has launched the effective service commitment, in fact, there are many method to avoid or reduce the fault, for example, regular maintenance of machine, equipment after each use, please be sure to remove all residue on the surface, regular inspection of equipment lubrication, tighten and run.

And check if abnormal situation get timely treatment, especially the understanding of structure and performance characteristics of the equipment, equipment failure, the user can according to the equipment maintenance manuals for equipment failures, and then according to the fault processing method for processing, with the increase of using time, stacker performance may reduce, if not timely maintenance or do not conform to the provisions of the case, will inevitably lead to material piling machine fault.

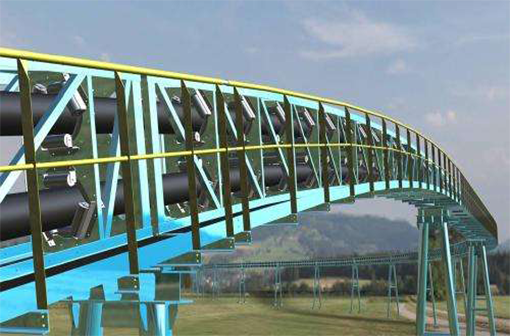

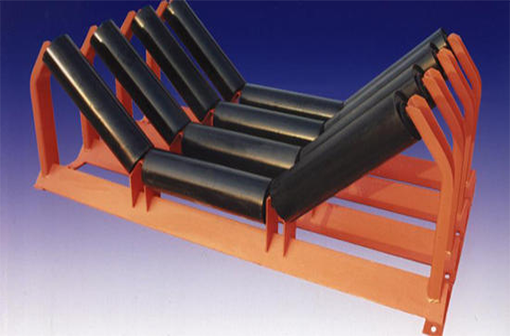

From this perspective, in the daily management and maintenance, material piling machine failure rate increased significantly, in addition, in the process of operation and use, if equipment technical parameters of the exception, when operating, material through the conveyor belt and tail stock transfer to the stacker, through the movement of the door frame and the operation of the stacker conveyor belt, in order to achieve the desired purpose, has been promoted and used in many fields.